In Conversation with “Biaosheng”

Canadian Standard Chartered recently accepted an interview with Tunnel Magazine, which was published in the Dec 2024/Jan 2025 issue. This interview focuses on the company's professional experience and innovative technologies in the field of tunnel engineering. In the interview, representatives from Canadian Standard Chartered Company shared their unique insights and practical experience in the company's new material "jelly slurry".

Tunneling Journal is an internationally renowned professional publication in the tunnel and underground construction industry. Since its inception in 1985, it has been providing comprehensive reports on technology, projects, trends, and challenges for the industry. This magazine is published six times a year, covering in-depth analysis of tunnel design, construction methods, mechanical equipment, safety measures, and environmental protection. As an authoritative publication in the industry, Tunnel Magazine has become an essential reference for experts and practitioners in the global tunnel industry with its high-quality editorial content.

This photo is taken from https://tunnellingjournal.com website

A new concept from China - jelly slurry

Contractors are looking for various uses of converting bentonite into "jelly slurry"

01. Stable strata

02. Reduce friction

03. Auxiliary correction

04. Soil pressure balance

When the contractor Shanghai Tunnel Engineering Co., Ltd. (STEC) built Jing'an Temple Station for Shanghai Metro Line 14 in 2019, they hoped to control ground subsidence. This is the first time that a large rectangular pipe jacking machine (8.7m x 9.9m) has been used to construct an underground station in soft soil layers. There is a Buddhist temple nearby that has a history of 1800 years, and if the ground subsidence is too large, the temple will be damaged.

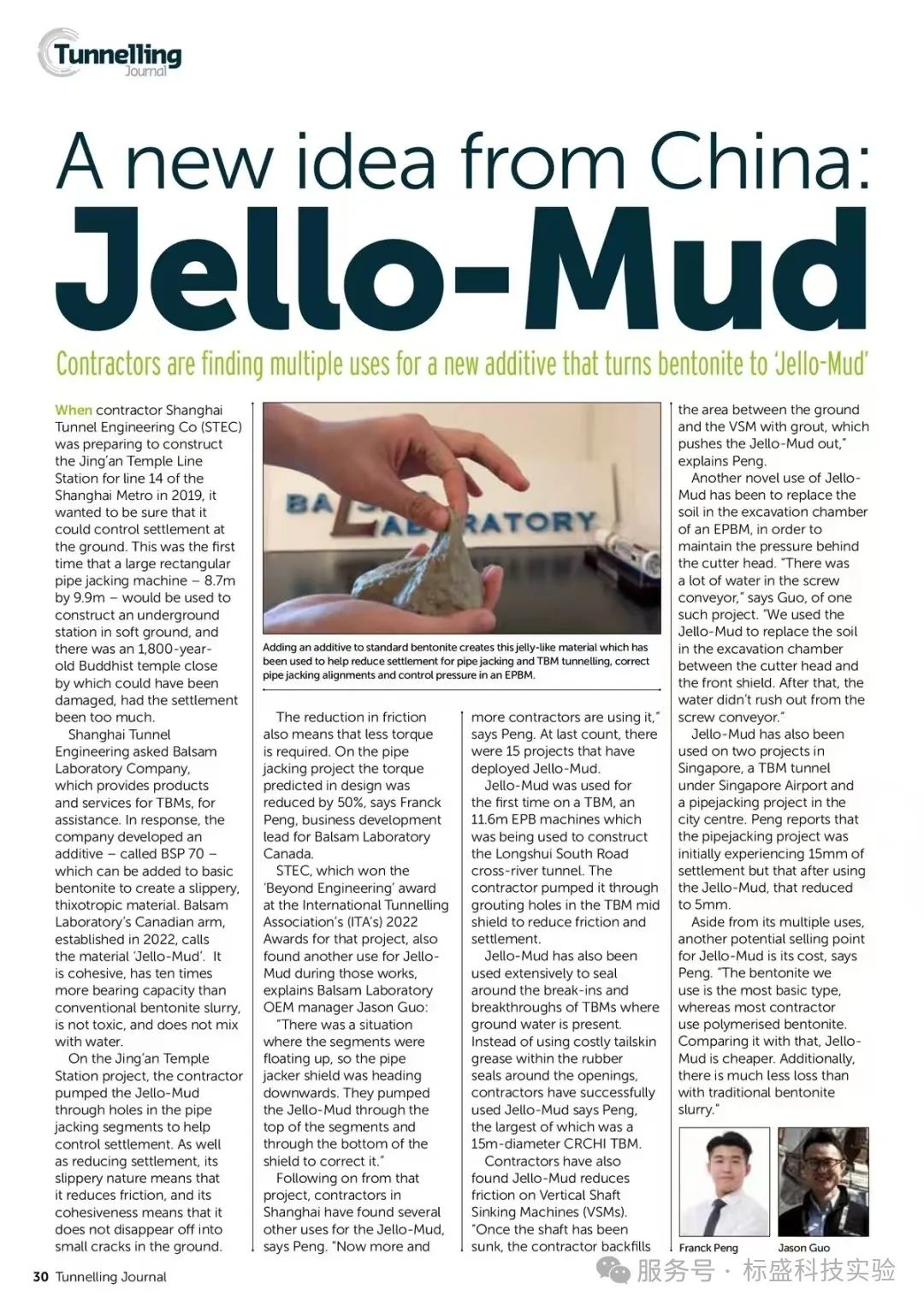

Shanghai Tunnel Engineering Co., Ltd. (STEC) seeks assistance from Biaosheng Technology Experiment (Shanghai) Co., Ltd., which specializes in providing products and services for tunnel excavation. In response, the company has developed an additive called BSP 70 that can be added to bentonite to create a smooth, thixotropic material. The Canadian branch of Biaosheng Technology Experiment (Shanghai) Co., Ltd. was established in 2022 and refers to this material as "jelly slurry". It has good cohesiveness, a bearing capacity ten times that of traditional bentonite slurry, is non-toxic, and is not miscible with water.

In the Jing'an Temple Station project, the contractor pumps jelly slurry outward through the injection holes of the pipe joints to help control settlement. In addition to reducing settlement, the cohesiveness of jelly slurry makes it less likely to be lost into small cracks in the formation. And the lubricity of jelly slurry also plays a role in reducing friction, which means that the torque during excavation is smaller< br />

Peng Houqi, Business Development Manager of Canada Standard Sheng: In this top-down project, the actual torque was reduced by 50% compared to the predicted torque< br />

02. The Jing'ansi Station project of Shanghai Metro Line 14 has therefore won the "Beyond Engineering" award at the International Tunneling Association (ITA) 2022 Awards. Another use of jelly slurry was also discovered in another project.

Guo Jiachen, OEM Manager of Canada Standard Sheng: There is a situation where the pipe joint floats up, and they adjust it by pumping jelly slurry to the top of the pipe joint and placing soil at the bottom of the pipe joint.

After the project, other contractors in Shanghai also discovered several other uses for jelly slurry. According to the latest statistics, 15 projects have used jelly slurry< br /> Peng Houqi, Business Development Manager of Canada Standard Sheng: More and more contractors are using jelly slurry now.

03. Jelly slurry was first used in a shield tunneling machine, which was an 11.6-meter earth pressure balance shield used to construct the Longshui South Road cross river tunnel. The contractor pumps the jelly slurry out of the shell through the injection holes in the middle shield to reduce friction and settlement. Jelly slurry is also widely used for tunnel door sealing during the initiation and reception stages of shield tunneling in underground water rich formations< br />

Peng Houqi, Business Development Manager of Canada Standard Sheng: The contractor did not use expensive shield tail sealing grease in the rubber seals around the tunnel portal, but successfully used jelly slurry for sealing, with the largest being a shield machine produced by China Railway Construction Corporation with a diameter of 15 meters.

04. The contractor also found that jelly slurry can play a role in reducing friction and stabilizing the formation during vertical shaft (VSM) construction.

Peng Houqi, Business Development Manager of Canada Standard Sheng: Once the sinking of the vertical shaft is completed, the contractor will use cement slurry to backfill the gap between the vertical shaft and the formation, thereby replacing the jelly slurry.

Another new use of jelly slurry is to inject it into the soil chamber of a soil pressure balance shield machine to establish and maintain the internal pressure of the soil pressure chamber, achieving the effect of soil pressure balance< br /> Guo Jiachen, OEM Manager of Canada Standard Sheng: There is a lot of water in the screw conveyor, and when we injected jelly slurry into the soil bin, the water did not overflow from the screw conveyor.

Jelly paste is also used in two projects in Singapore, the tunnel under Changi Airport and the top pipe project in the city center< br /> Peng Houqi, Business Development Manager of Canada Standard Sheng: The top pipe project initially experienced a settlement of 15 millimeters, but after using jelly slurry, the settlement was controlled to 5 millimeters.

In addition to the various uses mentioned above, another potential selling point of jelly slurry is its cost. The bentonite we use is the most basic type, while most contractors use polymerized bentonite. Compared to it, jelly slurry is cheaper. In addition, compared to traditional bentonite slurry, jelly slurry is less likely to be lost into the formation and the amount of loss is much smaller.